Equipment recommendations for small-scale camembert production in Australia present unique challenges that can make or break your cheese making success. Many artisan producers struggle with inconsistent results, failed batches, and equipment that simply can’t deliver the precision needed for creating authentic camembert cheese with its signature creamy texture and distinctive white rind.

Why Equipment Choice Makes or Breaks Your Camembert

Creating authentic camembert requires precise control at every stage, from gentle heat application during coagulation to maintaining optimal conditions during the aging process that develops the characteristic soft, gooey interior. Poor equipment choices lead to inconsistent temperatures, uneven curd cutting, and failed batches that waste both time and quality milk from cows.

The difference between success and failure often comes down to temperature precision and proper curd handling. Professional equipment ensures the delicate balance needed to transform milk into the foundation of exceptional camembert cheese that develops the molten texture and complex flavour profile inspired by traditional Normandy methods, while produced locally in Australia.

Temperature Control Challenges

Professional camembert production requires maintaining 32°C for extended periods during coagulation, then precise temperature control throughout aging. Basic kitchen equipment simply cannot provide the consistency needed for developing the complex flavor and texture that makes quality camembert so sought after. Temperature fluctuations create uneven ripening, poor rind development, and cheese that lacks the rich, earthy notes and creamy richness that defines authentic camembert de Normandie.

Curd Formation and Texture Development

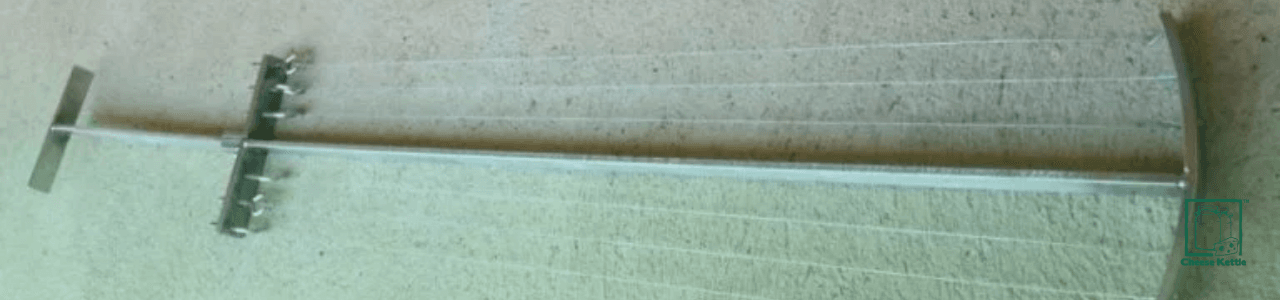

A precision curd cutter, such as the Swiss Style Cheese Curd Cutter or multi-blade cheese harps, is highly recommended for achieving uniform curd size. Consistent cutting directly impacts moisture content and final texture. Inconsistent cutting creates uneven drainage patterns, leading to cheese with varying moisture levels throughout each wheel. This affects both the initial texture and how the cheese ripens, potentially creating sections that remain firm while others become overly soft during the aging process, preventing the uniform gooey interior that makes camembert perfect for baking in the oven.

Essential Equipment for Professional Results

The foundation of successful camembert production relies on specialized equipment designed specifically for soft cheese making. Each piece serves a critical role in transforming cow’s milk into the creamy, rich camembert that develops its characteristic flavour and texture over three to five weeks of careful aging, depending on the desired maturity and style.

Professional-grade equipment ensures consistent results while meeting Australian food safety standards, supporting both artisan and small commercial production goals that create cheese suitable for serving with crackers, pairing with honey and walnuts, or enjoying as a dip with crusty bread.

Cheese Making Vats and Heating Systems

The foundation of successful camembert production starts with proper heating equipment that provides gentle, even heat distribution throughout your milk. The 200 Ltr Cheese Making Kettle Vat offers food-grade stainless steel construction with jacketed heating systems designed for the precise temperature control camembert demands. This capacity suits producers making 4-8 wheels per batch while maintaining the gentle heating essential for proper curd development that creates the soft, buttery texture traditional to normandy-style cheese.

For smaller operations or those with limited electrical infrastructure, a 240V Single Phase Cheese Vat provides commercial-grade temperature control while running on standard household service. Many rural producers also choose to upgrade to three-phase power for larger-scale production, but single-phase vats remain a flexible entry-level option.

Heating System Benefits

Jacketed heating systems distribute heat evenly throughout the milk, preventing hot spots that can damage proteins and affect curd formation. This gentle heating preserves the delicate structure needed for developing camembert’s characteristic texture while ensuring consistent coagulation that supports proper aging. The controlled heating also helps develop the complex flavor compounds that give finished camembert its distinctive taste profile, creating cheese that becomes beautifully molten when served warm or baked with toppings like garlic slices and rosemary sprigs.

Precision Temperature Monitoring

Accurate temperature measurement proves critical for camembert success, as even minor variations can significantly impact both texture and flavor development. Commercial-grade dairy thermometers with deep penetration provide precise readings while maintaining the gentle conditions needed for proper coagulation. The stainless steel construction includes secure attachment systems, enabling continuous monitoring without manual intervention during critical heating phases.

Digital alternatives offer enhanced precision with fine resolution, providing the accuracy needed for consistent results. These models feature waterproof construction and clear displays that remain visible throughout the heating process, ensuring the milk reaches exact temperatures needed for developing the creamy, rich interior that makes camembert perfect for spreading on bread or serving as an elegant dish paired with wine.

Curd Cutting and Processing Equipment

The Swiss Style Cheese Curd Cutter enables precision cutting that ensures uniform curd size essential for consistent camembert texture. Adjustable blade spacing allows customization for camembert’s specific requirements, where properly sized cubes create optimal surface area for whey drainage while maintaining moisture levels necessary for the creamy interior that defines quality camembert cheese.

Uniform curd size directly impacts how the cheese ages and develops its characteristic flavor profile over the traditional three weeks ripening period. Properly cut curds drain evenly, creating consistent moisture content that supports uniform ripening throughout each wheel, ensuring the development of the white, bloomy rind and soft interior that makes camembert delicious when served at room temperature or warmed in the oven.

Traditional Cheese Harps

Food-grade stainless steel cheese harps provide an alternative cutting approach with custom sizing to match specific vat dimensions. These tools ensure consistent curd size while preventing tearing that can occur with improvised cutting methods. Proper cutting preserves the delicate curd structure needed for developing the texture that makes camembert perfect for baking with olive oil and garlic or serving with apple slices and nuts.

Molding and Aging Equipment

Proper molding and aging equipment transform properly cut curds into the distinctive wheel shape and develops the complex flavors that make camembert such a treasured cheese. This stage requires specialized tools that support controlled drainage and create the ideal environment for rind development that protects the soft, creamy interior.

The molding process establishes the foundation for proper aging, while controlled aging environments ensure the development of camembert’s signature soft texture and rich, buttery flavor that pairs beautifully with traditionally served accompaniments like crusty bread, honey, or a glass of light red wine.

Camembert Molds and Draining Systems

Traditional camembert molds create the classic wheel shape that has been produced in Normandy for generations, following techniques developed by Marie Harel and other pioneering cheese makers. Food-grade construction provides durability needed for repeated use while allowing controlled whey drainage that develops proper texture. Quality kits typically include multiple molds, enabling batch production of several wheels simultaneously.

Proper drainage systems support the initial drying phase that prepares the cheese surface for rind development. Specialized draining equipment ensures adequate air circulation while preventing moisture buildup that can interfere with the formation of the white, bloomy rind characteristic of quality camembert that becomes perfectly ripe after three weeks of careful aging.

Aging Environment Controls

Camembert requires controlled aging environments with specific temperature and humidity levels to develop its signature soft texture and rich flavor over the traditional aging period. Dedicated aging containers or rooms with proper air circulation support beneficial mold development that creates camembert’s protective white rind while developing the complex earthy notes and buttery richness that make the cheese so distinctive.

Professional aging setups include monitoring systems that maintain consistent conditions throughout ripening. This controlled environment prevents contamination while supporting the biochemical processes that develop camembert’s characteristic flavor profile, creating cheese that spreads beautifully on crackers, melts perfectly when baked, or serves elegantly with dried cranberries and walnuts.

Supporting Production Systems

Beyond the core cheese making equipment, successful camembert production requires supporting systems that ensure food safety compliance and maintain consistent quality. These systems work together to create the controlled environment necessary for producing consistently delicious camembert that meets the standards expected from quality artisan cheese.

Proper supporting equipment ensures regulatory compliance while maintaining the quality standards that distinguish artisan camembert in the competitive cheese market, supporting production of cheese suitable for retail sale, restaurant service, or direct farm sales.

Pasteurization Equipment

Australian regulations require milk used for retail cheese production to be pasteurised to ensure food safety, except for very limited experimental raw milk cheese trials under FSANZ oversight. This means raw milk Camembert is not legally permitted for general sale in Australia. Pasteurisation systems are therefore essential for compliance, while still supporting the development of complex flavours. The 50 Ltr Pasteurizer for Milk provides entry-level batch pasteurization suitable for artisan production, while the 100 Ltr Milk Pasteuriser with Chiller offers integrated cooling for rapid temperature reduction after heat treatment.

These systems ensure regulatory compliance while preserving milk quality needed for developing the complex flavors that make camembert special. Energy-efficient models with heat recovery reduce operating costs while providing the precise control essential for producing consistently delicious camembert with authentic taste and texture that rivals traditional Normandy production.

Cleaning and Sanitization Systems

Food safety requirements mandate comprehensive cleaning protocols for all equipment contacting cheese during production. Stainless steel construction throughout ensures compatibility with approved sanitizing agents while preventing bacterial contamination that could compromise cheese safety and flavor development. Dedicated cleaning equipment reserved exclusively for cheese production prevents cross-contamination that might affect the delicate aging process.

Regular equipment maintenance and calibration ensure continued compliance with food safety standards while maintaining the quality control needed for producing ripe, flavorful camembert that develops the proper texture and taste profile expected from quality artisan cheese.

Building Your Production System

Creating a successful camembert production operation requires careful planning and strategic equipment selection that supports both immediate needs and future growth. The right equipment foundation enables consistent quality while providing flexibility for scaling production as demand increases for your delicious, creamy cheese.

Strategic equipment choices establish production capabilities that support business development while maintaining the artisan quality that distinguishes exceptional camembert in the marketplace, whether sold in traditional wooden boxes, served at tastings with wine pairings, or featured in restaurant dishes.

Starter Equipment Package

New producers should begin with core equipment including a dedicated cheese vat with heating capability, precision thermometer, Swiss Style Cheese Curd Cutter, and proper molding equipment. This foundation provides the control needed for consistent results while supporting gradual expansion as production scales and demand grows for your camembert cheese.

Starting with quality equipment prevents costly replacements while building skills with professional tools. This approach ensures consistent product quality that creates camembert with the authentic flavor and creamy texture customers expect, whether served warm from the oven with a drizzle of olive oil, paired with champagne for special occasions, or enjoyed simply spread on crusty bread.

Scaling Considerations

As production grows, consider upgrading to larger capacity systems while maintaining precision control needed for quality cheese production. The 200 Ltr capacity provides an excellent balance between commercial viability and manageable operation size. Additional equipment like automated systems can be added as demand increases, supporting production of cheese suitable for retail distribution, restaurant partnerships, or specialty food markets.

Quality equipment choices from the beginning establish production capabilities that support business growth while maintaining the consistent quality standards that differentiate artisan camembert in the competitive cheese market, ensuring each wheel develops the proper texture, flavor, and appearance that customers expect from premium camembert.

Conclusion

Take your camembert production to the next level with the Swiss Style Cheese Curd Cutter from CheeseKettle. This precision tool delivers the uniform cutting essential for consistent texture and proper aging that creates camembert with authentic flavor and creamy richness that becomes perfectly gooey when baked and delicious when served with your favorite recipe combinations.

Contact CheeseKettle today to discover how the Swiss Style Cheese Curd Cutter can help you produce exceptional camembert cheese with the professional quality that makes every wheel perfect for baking with garlic and herbs, serving with wine and crackers, or enjoying with traditional accompaniments that highlight the rich, buttery texture and complex flavor profile that defines quality camembert.