Edam is a semi hard cheese from cow’s or goat’s milk. This cheese originated from the northern regions of the Netherlands. It is typically formed into a round (boule) shape rather than being pressed. Young Edam has a mellow creamy taste with mild nutty undertones. When left to age, its taste intensifies, giving a drier and more crumbly consistency.

Here’s a recipe for making Edam cheese.

Yield: approximately 900g of Edam Cheese

Aging: 1 month or more

Ingredients

1. 7.5 L (2 gallons) milk (not ultra pasteurized)

2. 1/2 teaspoon MM100 mesophilic starter culture

3. 1 teaspoon Annatto or cheese coloring diluted in 1/3 cup cool water

4. 1/2 teaspoon liquid rennet diluted in 1/4 cup cool water

5. Cheese salt

6. ¼ teaspoon Calcium Chloride (use only with pasteurized milk)

Equipment

1. Large pot

2. Good thermometer

3. Measuring spoons

4. Curd knife or curd cutter

5. Slotted ladle

6. Draining mat

7. Cheese cloth or butter muslin

8. Edam cheese hoop

9. Draining mat

10. Cheese press

Instructions

Reminder: Sterilize all your equipment before making cheese.

1. Slowly heat the milk to 31.1° C (88° F).

2. Once the target temperature is reached, turn off the heat.

3. Add the Calcium Chloride and the annatto to the milk.

4. Sprinkle the mesophilic starter culture on the surface of the milk. Stir in an up and down motion.

5. Cover the pot and let the milk ripen for 30 minutes.

6. Slowly heat the milk back to 31.1° C (88° F) for the next 10 minutes. Maintain the temperature.

7. Add the rennet. Stir in a slow up and down motion for 1 minute.

8. Cover the pot and let the milk set for 45 minutes while still keeping the temperature at 31.1° C (88° F).

9. Once you have a clean break, cut the curds into ½ inch cubes.

10. Let the curds rest for 5 minutes.

11. Slowly increase the temperature to 33.3° C (92° F) for the next 15 minutes. Stir continually to prevent the curds from sticking together (also called matting). The curds should shrink and become firmer during this process. Once you’ve reached the target temperature, turn off the heat.

12. Let the curds sit uncovered for 30 minutes. In the meantime, heat some water.

13. The curds will have sunk to the bottom of the pot. Ladle the whey into another container. Remove the whey up to the level of the curds. Save the whey for later use.

14. Stir the curds for 20 minutes or until they begin to mat and cling together.

15. Slowly pour hot water to the pot until the temperature goes up to 37.2° C (99° F). Keep the curds at this temperature for 20 minutes, allowing the curds to settle again.

16. Line the colander with a clean damp cheese cloth or butter muslin. Suspend the colander over a large bowl.

17. Ladle the curds into the colander and allow to drain for 5 minutes.

From this point, you have two processes you can follow.

Unpressed Edam Cheese

18. Add 1 tablespoon of cheese salt.

19. Divide the curds evenly into two portions. Put each portion into its own cheese cloth and tie it up. Shape the curds into a ball. Hang it for 30 minutes to drain thoroughly.

20. Heat the saved whey to 50° C (122° F). Remove from heat.

21. Take the cheese balls out of the cheese cloth and submerge them in the warmed whey for 20 minutes. Be sure to keep the temperature at 50° C (122° F) during this time. Turn the balls of cheese several times within the whey during this process.

22. Redress the cheese with cheese cloth and hang it up to drain for 6 hours.

23. Prepare the brine. Mix 737 g (26 ounces) of salt in 3.7 L (1 gallon) of water. Chill at 10° C (50° F).

24. Remove the cheese from the cloth and submerge in the brine. Put it in the refrigerator overnight.

25. Take the balls of cheese (boules) out of the brine. Pat dry with a paper towel. Place the boules on a draining mat and air dry for 1 to 2 days.

Pressed Edam Cheese

18. From procedure number 17 above, gather the four corners of the cheese cloth and bring them together to form a draining sack. Shape the curds into a ball.

19. Drop the curds into an edam cheese hoop. Pull up the edges of the cheese cloth to prevent folds and wrinkles.

20. Press firmly with your hands to set the curds well into the hoop.

21. Cover the hoop with a follower and press the cheese at 7 kg (15 lbs.) of pressure for 15 minutes.

22. Press at 11 kg (25 lbs.) for 1 hour, then at 16 kg (35 lbs.) for another 2 hours.

23. Press again at 18 kg (40 lbs.) for another 2 hours.

24. Leave the cheese in the hoop and place in a cool area with a temperature of 16° C (62° F).

Final Process

Wax the cheese. Ripen at 12° C (55° F) at 85% humidity for 2 to 6 months. The longer the aging time, the drier the edam cheese becomes. Flip the cheese twice a week during the aging period.

Featured Cheese Culture

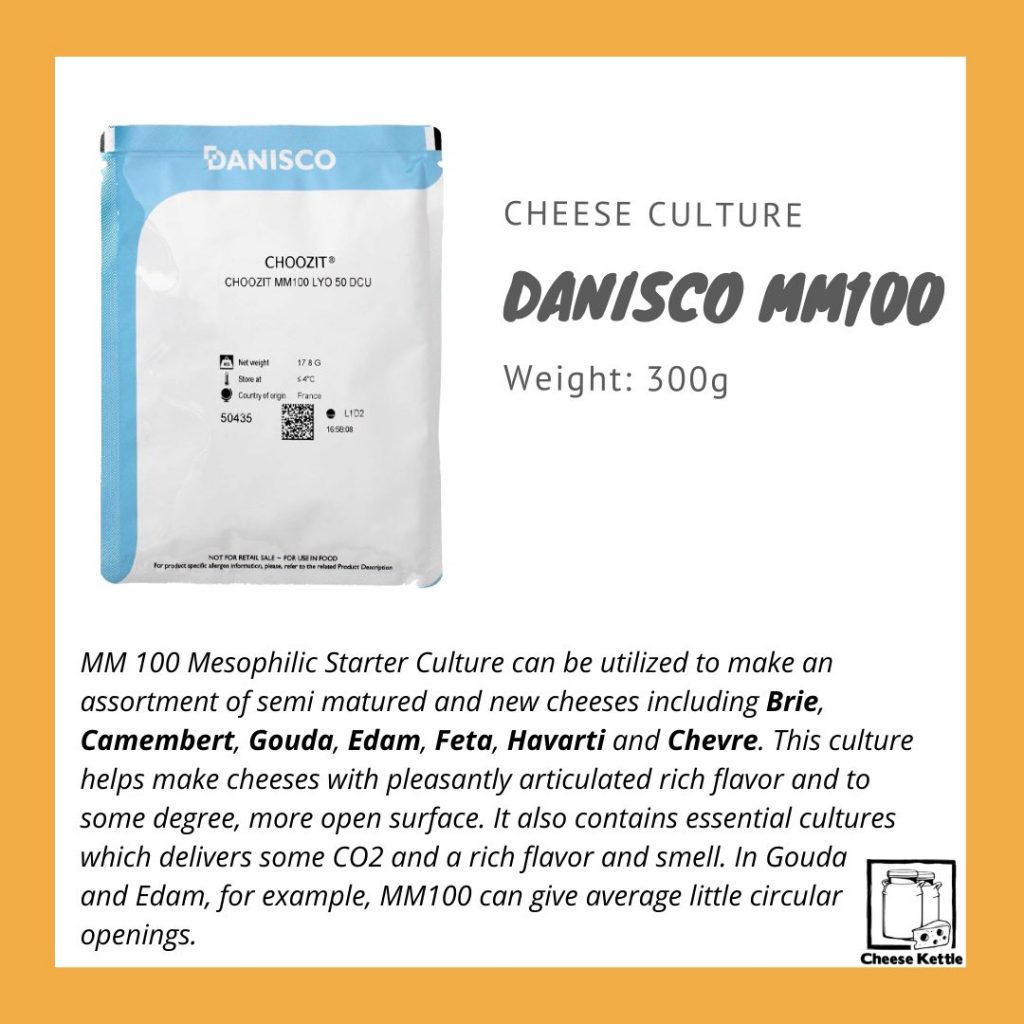

Get your MM100 Mesophilic Starter Culture at our SHOP.